How will 3D printing organs work?

The short answer

3D printing organs uses bioinks—materials made from living cells and gel-like substances that act as scaffolds, giving cells a structure to grow on. Simple tissues have already been printed, but printing complex organs like hearts or kidneys is still a work in progress due to challenges like building blood vessels and preventing immune rejection.

The long answer

Printing organs may sound like science fiction — but it's well on its way to becoming reality. And it couldn't come sooner: Currently hundreds of thousands of patients await transplants, but donor organs are in short supply.

Let's dig into how bioprinting works and the major challenges researchers still face.

What is 3D printing?

If your experience with printing stops at your office's laser printer (and avoiding paper cuts), it could be hard to wrap your head around 3D printing. But the concept is relatively simple.

Source: Vidavista

Just as a 2D printer follows instructions to place ink, a 3D printer does the same except it prints in multiple layers. Replace the ink with a material like plastic and you can build structures into the third dimension.

What are 3D printed organs made out of?

A 3D bioprinter operates on the same principles as 3D printing but with a heck of a lot more complexity (and different ink).

A 3D printed organ is a replica of a body part or bodily tissue printed using bioink, a material containing living cells designed to mimic human tissue. Bioinks must support the growth of living cells, maintain structure during and after printing, and be non-toxic and non-inflammatory.

While each bioink is specially designed for whatever is being printed, they are often a mix of one or more types of living cells, water-rich molecules called hydrogels that act as scaffolds for cell growth, and growth-promoting proteins and peptides.

How does 3D printing organs work?

Here is a simplified overview of the steps involved in 3D printing an organ.

Step #1: Create a 3D model of the organ.

"Abdominal Aorta MRI Color MIP SAA" by Nevit Dilmen is licensed under CC BY-SA 3.0.

The patient will undergo precise scans, such as MRI scans, to gather data on the organ to be replaced. This data is used to create a specific 3D model that will fit the patient's anatomy.

Step #2: Harvest and grow the patient's cells.

Ideally the patient's own cells are harvested and grown in a lab to create the foundation of the bioink used in the printing process. Using the patient's cells minimizes the risk of organ rejection, which is one of the key advantages of 3D printing organs. These cells are mixed with the other components of the bioink, like growth factors and hydrogels.

Step #3: The 3D model is printed using the bioinks.

Armed with a model and the bioink, we're now ready to begin printing. While there are a variety of bioprinting techniques, a common method is extrusion-based bioprinting.

The bioinks are loaded into printing chambers and pushed to go out the end of the nozzle as a continuous filament. The nozzle is rarely wider than 400 microns in diameter and produces filament about as thick as a human fingernail.

"Bioprinting" by Philip Ezze is licensed under CC BY-SA 4.0.

The bioink is either printed onto a flat surface or into a liquid bath to hold the structure in place until it stabilizes, a method used for particularly delicate material like heart tissue. Over several hours, the printer builds the organ from thin, layered strands of bioink.

(Psst.. I found these really, really cool images during my research, but I can't include them here because of copyrights, so click to check them out!)

Step #4: Post-printing process occurs.

"Specialized containers for cell processing." by WFIRM.

After the organ is printed, there are post-printing processes to undergo, depending on which tissue was printed. For example, the tissue will be placed in a bioreactor to provide controlled conditions, like temperature, UV light, and oxygen levels, to help the tissue mature. Mechanical stimulation, like stretching, could also occur at this stage to aid in the tissue developing function.

Once the organ is developed and functioning, it would be implanted into the patient during an organ transplant surgery.

Have we successfully transplanted a 3D-printed organ?

You might be wondering, "Have we actually pulled this off?" Yes! Scientists have 3D printed and implanted some human tissues, including an ear and a bladder.

As for more complex organs like hearts and lungs, scientists believe we're at least 10-20 years away from 3D printing being used clinically.

What are the key challenges with 3D printing organs?

The complexity of human anatomy and technological hurdles with 3D printing tissue present a few key challenges yet to be solved with 3D printing.

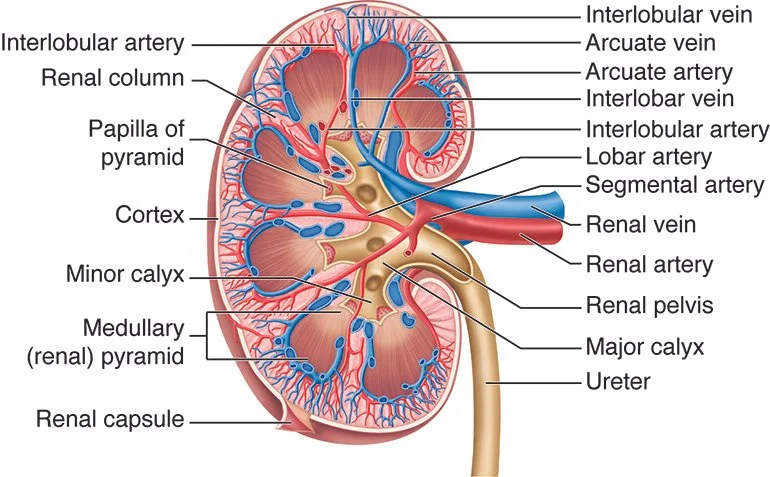

Challenge #1: Mimicking an organ's vascular network

3D printing the shape of a kidney is relatively easy compared to recreating its complex network of blood vessels.

My printer (RIP) could have barely printed this image, let alone an organ.

"Blood and Nerve Supply" by Cenveo is licensed under CC BY 3.0 US.

As with all printing, 3D printing comes with resolution constraints. The millimeter details of an organ's vascular network can be difficult to execute with today's technology. Scientists are exploring different bioinks with additives that could encourage vascularization. Speaking of which...

Challenge #2: Designing the best bioinks

There's a bit of a Goldilocks problem when it comes to bioinks. Natural materials, like collagen, gelatin, and alginate, are highly compatible when it comes to supporting cell growth — but they're difficult to print. On the other hand, synthetic materials can increase "printability" but may be less hospitable to cells.

Finding the right blends of biomaterials to make up bioink is an ongoing process to ensure a good print job and compatibility with living cells. And if that doesn't seem challenging enough, different parts of an organ may require different bioinks to match their function.

Challenge #3: Minimizing the risk of rejection

As with any organ transplant, there's a risk of the patient's body rejecting the new tissue. While 3D printing comes with the advantage of using the patient's own cells, the other components that make up the bioink could be identified as foreign invaders by the immune system.

Curious about how the world works?

Today You Should Know is a free, weekly email newsletter designed to help you learn something new every Friday.

Subscribe today 👇

Check out some other curious questions:

Sources

BBC News. (2022, October 30). Could 3D printing be the future of organ transplants? - BBC News. YouTube. https://www.youtube.com/watch?v=IUx_vkB3PFc&ab_channel=BBCNews

Carroll, D. (n.d.). 3D bioprinted heart provides new tool for surgeons. College of Engineering at Carnegie Mellon University. https://engineering.cmu.edu/news-events/news/2020/11/18-3d-printed-heart.html

CELLINK . (2024b, January 10). 3D Printed Organs: How, Why & When. CELLINK. https://www.cellink.com/blog/3d-printed-organs/

CELLINK. (2024a, January 31). What is a bioink?. CELLINK. https://www.cellink.com/what-is-bioink/

Jones, T. (2019, October 17). How to 3D print human tissue - Taneka Jones. YouTube. https://www.youtube.com/watch?v=uHbn7wLN_3k&ab_channel=TED-Ed

NSF Engines: Piedmont Triad Regenerative Medicine Engine. (2025, February 24). Bioink for 3D Bioprinting. NSF Engines: Piedmont Triad Regenerative Medicine Engine. https://regenmedengine.com/innovative-technologies/bioink/

Rogers, K. (2023, March 10). When we’ll be able to 3D-print organs and who will be able to afford them. CNN. https://www.cnn.com/2022/06/10/health/3d-printed-organs-bioprinting-life-itself-wellness-scn/index.html

Rogers, S. (2025, March 12). The Future of Medicine: 3D Printers Can Already Create Human Body Parts. Interesting Engineering. https://interestingengineering.com/health/doctors-can-finally-3d-print-human-tissue-ligaments-and-tendons

World Health Organization. (2024, May 30). Seventy-seventh World Health Assembly – Daily update: 30 May 2024. World Health Organization. https://www.who.int/news/item/30-05-2024-seventy-seventh-world-health-assembly---daily-update--30-may-2024

It’s like an American accent but with calendars.